Feb 2017

Identifying the Importance of a Fleet Maintenance Program

Controlling fleet maintenance costs can be one of the most challenging and important aspects of an effective fleet program. The level at which a vehicle is maintained throughout its lifecycle can directly affect both immediate maintenance expenditures as well as the vehicles resale value. The success of a fleet maintenance program not only depends on the driver, but also your fleet partner’s ability to analyze data while properly regulating the pricing and the completed work.

An obvious benefit of an effective fleet maintenance program is the National Account Pricing that it offers. When looking at a per-transaction basis, National Account pricing was 46% less than non-National Account pricing during 2016. But as noted above, the responsibility of utilizing vendors that offer this national pricing is in the hands of your drivers. Simple incentive/penalty based programs can help to curtail the use of non-national accounts. Many fleet apps, such as EMKAY’s Driver 360, also have Preferred Vendor Locator tools to help drivers find in-network shops no matter where they are.

An example of this extremely important pricing advantage can be seen when looking at the Major Maintenance Vouchers. Major repairs typically include repairs on the engine, transmission, exhaust, electrical, etc… When looking at 2016 data, the average voucher for an out-of-network major repair was $788, while the average voucher for in-network major repairs was $578.

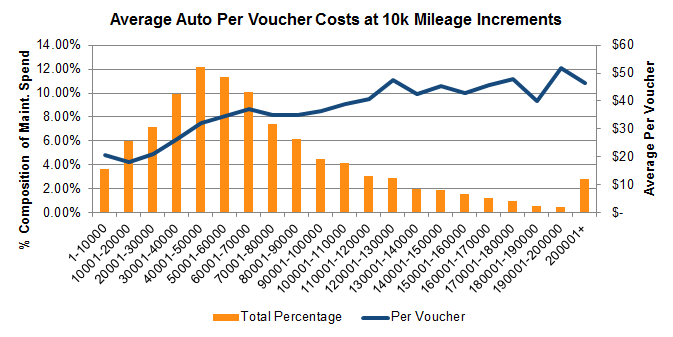

However, there’s much more to a successful fleet maintenance program than just national account pricing. The importance of analytics cannot be understated when it comes to controlling maintenance expenditures. When utilized properly, these data sets can be used as predictive modeling tools to identify trends before they become apparent. Fleet management companies should be collecting and analyzing millions of data points that then enable them to identify trends on a vehicle-by-vehicles basis. Such identifiable trends include determining at what mileage a given vehicle is likely to suffer catastrophic failure, average brake expenses at 10k mileage intervals, tire wear and tread life analyses, and when the average maintenance vouchers begin to spike for a given make, model, trim, and engine offering.

A final aspect of an effective fleet maintenance program is centered on the approval policies that your company establishes. While many programs pre-approve certain work at each mileage interval, many companies also give their drivers the ability to add work to a given purchase order. Even if drivers are only able to add a small amount of work, this can add up very quickly. History has shown that as much as 40% of driver-authorized repairs are unnecessary, unwarranted, or fraudulent. So while it may seem like an efficiency gain to forgo having the shops contact your fleet partner for service adds, trained maintenance advisors are much better equipped to correctly diagnose what is actually needed. These maintenance advisors will also have access to the vehicle’s entire maintenance history, making it easy for them to determine if a requested service is actually needed.

When looking at a maintenance program in its entirety it becomes apparent that when utilized properly, it can greatly reduce and control maintenance expenditures. It’s important for companies to ask their fleet providers to not only prove their program’s effectiveness through the pricing advantages, but also through their use of advanced analytics and control measures that are necessary for a truly beneficial program.